Alligatoring is patterned cracking in the surface of the paint film that resembles the regular scales of an alligator.

Alligatoring is patterned cracking in the surface of the paint film that resembles the regular scales of an alligator. What Causes It?

This problem may be caused by applying an extremely hard, rigid coating, like an alkyd enamel, over a more flexible coating, like a latex primer.

Applying the topcoat before the undercoat is dry may also cause alligatoring.

Alternatively, the natural aging of oil-based paints as temperatures fluctuate causes constant expansion and contraction that can result in a loss of paint film elasticity.

How to Solve It

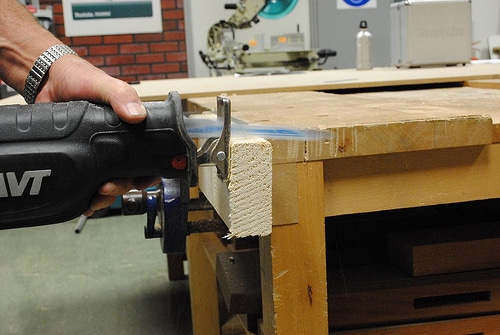

Completely remove the existing oil paint by scraping and sanding the surface. You can use a heat gun to speed up work on large surfaces, but take care to avoid igniting paint or substrate.

The surface should be primed with a high-quality latex or oil-based primer, then painted with a top-quality exterior latex paint.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

A blister can form when vapor expands between a coated surface and the film that protects it.

What Causes It?Anything from humidity to construction defects to a lack of effective vapor barriers often can lead to moisture condensation on wood siding, which generates pressure on the wood and its coating. As the surface dries, water evaporates, but the paint film does not recover.

Blisters can also form when painting in direct sunlight with solvent-based coatings on a surface that is too warm. When you apply thicker coats, or re-coat before a previous coat has completely dried, the paint surface can dry before the solvent releases from the underlying film. This traps the solvent, which can expand and cause blisters.

How to Solve ItTo remove blistered paint, sand and scrape peeling paint to the bare wood. Prime the exposed areas and repaint them.

For blisters caused by moisture, minimize any future problems by repairing loose caulking and installing vents or exhaust fans. These will allow moisture to evaporate before it can penetrate wood siding.

For large blistered areas, use a high-pressure washer or a heat gun to speed up the process of removing the paint.

Remember that blisters occur only in fresh coats of paint. When they break, they contain no liquid and do not indicate

a defect in the wood. They can be removed by scraping and sanding.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

A fine powder can occur on the surface of the paint film during weathering, which can cause color fading.

A fine powder can occur on the surface of the paint film during weathering, which can cause color fading. What Causes It?Although some degree of chalking is a normal, desirable way for a paint film to wear, excessive film erosion can result in heavy chalking.

The use of a lower-quality, highly pigmented paint or an interior paint can cause the paint to erode prematurely and cause chalking.

How to Solve ItFirst, remove as much of the chalk residue as possible, using a stiff bristle brush (or wire brush on masonry) and then rinse thoroughly with a garden hose; or use power washing equipment.

Check for any remaining chalk by running a hand over the surface after it dries. If noticeable chalk is still present, apply a quality oil-based or acrylic latex primer (or comparable sealer for masonry).

Repaint with a quality exterior coating. If little or no chalk remains and the old paint is sound, no priming is necessary.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

This problem occurs when the paint film erodes and the resulting residue appears chalky.

This problem occurs when the paint film erodes and the resulting residue appears chalky. What Causes It?Chalk run-down occurs when paint erodes excessively onto another area below (a brick foundation, for example), ruining its appearance. The problem has a number of causes.

First, the use of a lower-quality, highly pigmented paint or an interior paint can cause the paint to erode prematurely. Factory-finished metal siding can also erode to cause this problem.

How to Solve ItFirst, remove as much of the chalk residue as possible by scrubbing any stained areas with a stiff brush and a detergent solution. Then, rinse the surface thoroughly. In cases of severe staining, an acid wash may be necessary. Either way, if the affected area dries to a different color, consider painting it with a quality latex paint. Eroding aluminum siding should be thoroughly cleaned (power washing recommended) before painting with a quality exterior latex paint.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

Paint can crack and flake, sometimes revealing the substrate.

Paint can crack and flake, sometimes revealing the substrate. What Causes It?Dry paint can split through at least one coat, which will lead to complete failure of the paint. Early on, the problem appears as hairline cracks. Later, flaking of paint chips occurs.

A variety of causes exist for cracking or flaking of paint. First, if lower-quality paint has been applied to the surface, it will have inadequate adhesion and flexibility. Another cause is that the paint was spread too thin on the surface.

Poor surface preparation, especially when the paint is applied to bare wood without priming, can also cause this problem. Finally, painting under cool or windy conditions can make latex paint dry too fast, causing it to crack.

How to Solve ItIf the cracking does not go down to the substrate, you may be able to correct it by removing the loose or flaking paint with

a scraper or wire brush, sanding the area to feather the edges, priming any bare spots, and repainting it.

If the cracking goes down to the substrate, remove all of the paint by scraping and sanding or use a heat gun. Then prime and repaint with a quality exterior paint.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

Dirt, dust particles, or other debris can accumulate on the paint film, which may resemble mildew.

What Causes It?Dirt can accumulate on lower-quality paints, especially lower grades of satin or semi-gloss.

Usually, dirt pickup is caused by soil splashing onto siding or results from air pollution, car exhaust, and flying dust collecting on the house body and horizontal trim.

How to Solve ItWash off all surface dirt before priming and painting. If unsure whether the problem is dirt or mildew, conduct a simple spot-test (see Mildew). Clean off dirt with a scrub brush and detergent solution, followed by a thorough rinsing with a garden hose. Heavier dirt accumulation may require the use of a power washer.

While dirt pickup can't be eliminated entirely, top-quality exterior latex paints typically offer superior dirt pickup resistance and washability. Also, higher-gloss paints are more resistant to dirt pickup than flat paints, which are more porous and can easily entrap dirt.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

Efflorescence or mottling appears as crusty, white salt deposits, leached from mortar or masonry as water passes through.

What Causes It?Efflorescence or mottling is caused by failing to adequately to prepare the surface by removing all previous efflorescence or when excess moisture escapes through the exterior masonry walls from the inside.

How to Solve itIf excess moisture is the cause, eliminate the source by repairing the roof, cleaning out gutters and downspouts, and sealing any cracks in the masonry with a high-quality, water-based all-acrylic or a siliconized acrylic caulk.

If moist air is originating inside the building, consider installing vents or exhaust fans, especially in kitchen, bathroom, and laundry areas.

Remove the efflorescence and all other loose material with a wire brush, power brush, or power washer; then thoroughly rinse the surface. Apply a quality water-based or solvent-based masonry sealer and allow it to dry completely; then apply a coat of top-quality exterior house paint, masonry paint, or elastomeric wall coating.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

Paint can lighten over time. This occurs on surfaces with sunny southern exposures.

What Causes It?

Fading or poor color retention can also be a result of chalking of the coating. One cause of fading is the use

of an interior grade of paint or lower-quality paint.

This can lead to a rapid degradation (chalking) of the paint film. Some paint colors are particularly vulnerable to UV radiation (most notably, certain bright reds, blues, and yellows).

Fading will also occur when tinting a white paint not intended for tinting, or overtinting a light or medium

paint base.

How to Solve ItWhen fading or poor color retention is a result of chalking,

it is necessary to remove as much of the chalk as possible. When you repaint the surface, be sure to use a quality exterior house paint in colors recommended for exterior use.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

Frosting appears a white, salt-like substance on the paint surface. Frosting can occur on any paint color, but it is less noticeable on white paint or light tints.

What Causes It?On masonry, frosting can be mistaken for efflorescence. Frosting forms mostly in protected areas (such as under eaves and open porch ceilings) that do not receive the cleansing action of rain, dew, and other moisture.

The use of dark-colored paints that have been formulated with calcium carbonate exterior may also cause this. Applying a dark-colored paint over a paint or primer containing calcium carbonate extender can also lead to this problem.

How to Solve It

Frosting can be a stubborn problem. It often cannot be washed off readily. The condition can also recur as a bleed-through even when a new top coat is applied.

In extreme cases, it can interfere with adhesion. The best remedy is to remove the frosting by wirebrushing masonry or sanding wood surfaces. Then rinse and apply an alkyd-based primer before adding a coat of high quality exterior paint.

Note: images provided by The Rohm & Hass Paint Quality Institute.

Lap Marks are the appearance of a denser color or an increased gloss where wet and dry layers overlap during paint application.

What Causes It?Failing to maintain a "wet edge" when applying paint or using low-solid, "economy" paint can both lead to the formation of lap marks.

How to Solve It

When painting, make sure to maintain a wet edge by applying paint toward the unpainted area and then back into the just-painted surface. This technique (brushing or rolling from "wet to dry" rather than vice versa) will produce a smooth, uniform appearance.

It is also wise to work in manageably sized areas, and to plan for interruptions at a natural break, such as a window, door, or corner.

Using a top-quality acrylic latex paint makes it easier to avoid lapping problems because higher solids (pigments and binder) content makes lapped areas more noticeable.

If the substrate is very porous, you should apply a primer or sealer to prevent paint from drying too quickly and reducing wet-edge time. Alkyd paints generally have superior wet-edge properties.

Note: Images provided by The Rohm & Hass Paint Quality Institute.

Image by

Image by  Image by

Image by  Image from

Image from  Background/Why You Need It

Background/Why You Need It